When we buy a product, we expect it to last. Whether it’s electronics, machinery, or even household appliances, reliability matters. For manufacturers, proving that reliability to customers often comes down to testing and data. One of the most widely used measures of reliability is MTBF analysis, short for Mean Time Between Failures.

In this guide, we’ll break down what MTBF analysis is, why it matters, and how it helps both manufacturers and consumers make informed decisions.

1. What MTBF Analysis Really Means

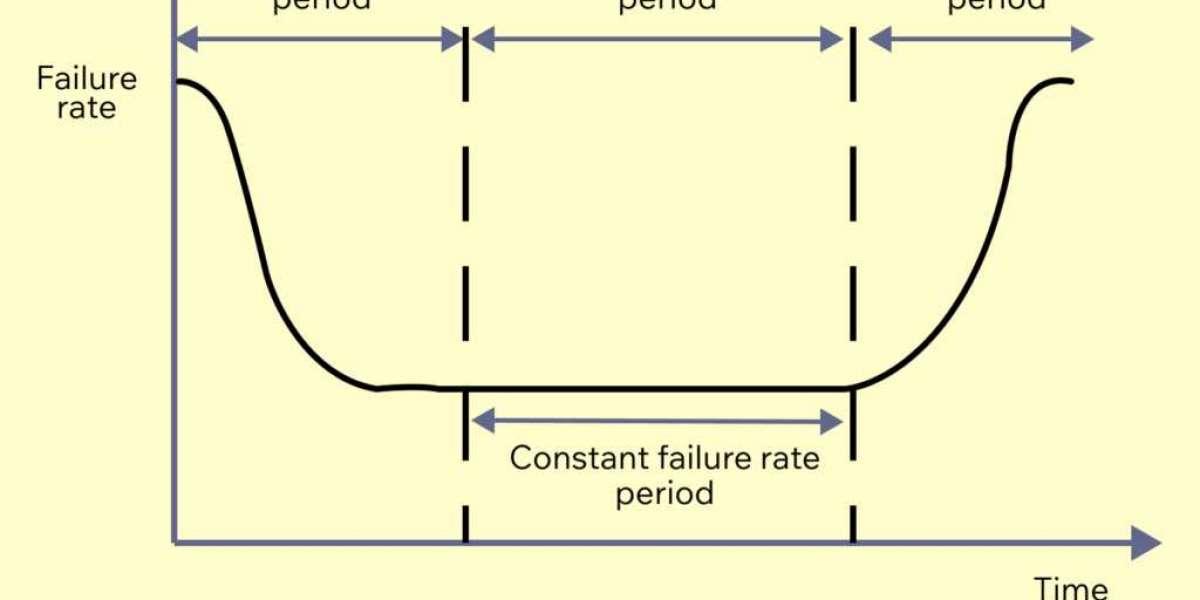

MTBF stands for Mean Time Between Failures. It’s a measure of how long a product or component can be expected to work before it fails. Unlike warranties, which simply cover replacement or repair, MTBF provides a data-driven estimate of reliability.

For example, if a product has an MTBF of 100,000 hours, it doesn’t mean it will last that long for every customer. Instead, it means that, statistically, across many units, the average time before failure is about 100,000 hours.

2. Why MTBF Matters to Consumers

From the outside, MTBF may sound like a technical detail only engineers need to know. But as a consumer, it affects you more than you think:

Peace of mind: Products with a higher MTBF are less likely to break down unexpectedly.

Lower costs: Fewer breakdowns mean fewer repairs or replacements.

Better value: Reliable products last longer, so you get more out of your purchase.

Think about the difference between a budget electronic device that fails after a year versus one that lasts for several years. That difference often comes down to reliability data like MTBF.

3. How Manufacturers Use MTBF Analysis

Manufacturers use MTBF analysis to design, test, and improve their products. By collecting data from testing and real-world use, they can estimate the average lifespan of components. This analysis helps them:

Identify weak points in design

Improve durability through better materials or engineering

Predict warranty claims and service needs

Build trust by providing reliable numbers to customers

A company that invests in MTBF testing shows it values transparency and customer trust.

4. The Difference Between MTBF and Lifetime

One of the biggest misconceptions about MTBF is that it represents product lifetime. In reality, MTBF is not the same as how long a single unit will last.

Lifetime is the total period a product can function before it becomes unusable.

MTBF is the statistical average between failures across many units.

For example, a light bulb might have a lifetime of 10,000 hours. But if a company tests hundreds of bulbs and measures the time between failures, the MTBF might be calculated differently depending on test conditions and failure rates.

5. MTBF in Different Industries

MTBF analysis isn’t just for electronics. It plays a role across industries:

Aerospace: Reliability is critical because failures can be life-threatening.

Telecommunications: Networks need high uptime, so equipment is tested for long MTBF.

Automotive: Parts with higher MTBF mean fewer breakdowns on the road.

Medical devices: Reliability ensures safety and consistent performance.

Whenever reliability is tied to safety, cost, or convenience, MTBF analysis becomes important.

6. What Consumers Should Look For

As a consumer, you may not always see MTBF data on product packaging, but when it’s available, it can be a useful comparison point. Here’s what to keep in mind:

Higher MTBF values suggest better reliability

Compare similar products to see which manufacturer provides reliability data

Check if MTBF claims are backed by industry standards (like Telcordia or MIL-HDBK)

Even if you don’t see MTBF numbers directly, brands that highlight reliability testing often produce more dependable products.

7. The Future of MTBF Analysis

As technology advances, so do methods of reliability testing. Companies are using simulations, digital twins, and AI-driven analysis to predict failures more accurately. This means MTBF analysis will only get more precise, helping both businesses and consumers make smarter choices.

For consumers, that means better quality products and clearer expectations. For manufacturers, it means being able to design with reliability in mind from the start.

Final Thoughts

MTBF analysis may sound technical, but it’s essentially about trust. It gives manufacturers a way to prove reliability, and it gives consumers confidence in their purchases.

Next time you buy something important—whether it’s electronics, a car part, or industrial equipment—remember that MTBF analysis might be behind the scenes helping ensure you get a product that lasts.