Construction work exposes your eyes to dust, debris, chemicals, sparks, and intense light every single day. Without proper eye protection, even a small accident can lead to permanent damage or total vision loss. That’s why construction site safety glasses are not just useful—they’re essential. These aren’t ordinary glasses. They’re built with strong materials like polycarbonate and Trivex to resist impact, offer UV protection, and block flying particles.

Whether you’re welding, cutting, or mixing chemicals, the right eyewear acts as your first line of defense. Wearing OSHA-compliant eyewear that meets ANSI Z87.1 standards ensures both safety and legal protection on every job site.

Why Eye Protection Is Critical on Construction Sites

Every day, construction workers face risks like dust, sparks, chemicals, and sharp objects. These things can get into the eyes and cause pain or even blindness. Sometimes, even bright lights or ultraviolet rays can hurt the eyes if they are not protected. These dangers make eye protection for job sites very important.

Without proper safety gear, workers can suffer from temporary issues like redness and blurriness, or serious injuries like chemical burns or loss of sight. Eye protection is not just a suggestion—it’s something every worker needs. The good news is that modern protective lenses for bright lights and other risks can keep eyes safe without causing discomfort.

What Are Construction Site Safety Glasses and How Do They Work?

Construction site safety glasses are made from strong materials like polycarbonate or Trivex. These lenses are stronger than regular plastic or glass and can handle hard hits. That’s why they are known as impact-resistant glasses. Some glasses are also certified as EN ISO 16321-1:2022 certified, which means they meet strict safety rules.

They are not like normal glasses. These safety glasses have special coatings that make them scratch-resistant and anti-fog. This means workers can see clearly even when it’s dusty or humid. Some designs include wraparound safety glasses that cover the sides of the eyes too, offering full-coverage eye protection.

OSHA Eye Protection Requirements for Construction Workers

According to OSHA, all workers on construction sites must wear eye protection if there is a risk of injury. The rule is simple: when something could hurt the eyes, safety glasses are required. That answers the common question: are safety glasses required on construction sites? Yes, they are. Many workers and employers turn to quick training options like OSHA 30 online $25 , but it's important to ensure that such programs are authorized and meet federal standards for job site safety.

OSHA also expects employers to provide safety gear and make sure workers wear it. This includes safety goggles for chemicals, welding goggles for construction, and glasses with durable safety lenses. All glasses must meet ANSI or EN ISO safety eyewear standards. Wearing compliant safety equipment can save lives and jobs.

Do You Legally Have to Wear Safety Glasses on Site?

Yes, the law says that if there is any risk to your eyes, you must wear safety glasses. If a worker refuses and gets hurt, both the worker and employer could face big problems. OSHA fines are high, and no one wants to be responsible for an avoidable accident.

Safety glasses are more than just advice—they are legally required PPE. Certified protective eyewear helps workers avoid penalties and injuries. These laws are strict for a reason. Construction eye injury prevention starts with following safety rules and using vision safety gear.

What Can Happen If You Don’t Wear Safety Glasses?

Many workers think it won’t happen to them, but eye injuries are more common than you’d expect. A small particle of dust or a drop of glue can lead to major damage. Some workers have had to stop working completely because of one simple mistake.

Not wearing safety glasses can lead to chemical burns, loss of vision, or permanent eye damage. These accidents are painful, expensive, and usually preventable. Using chemical splash goggles and UV protection glasses reduces risk and helps workers stay safe throughout the day.

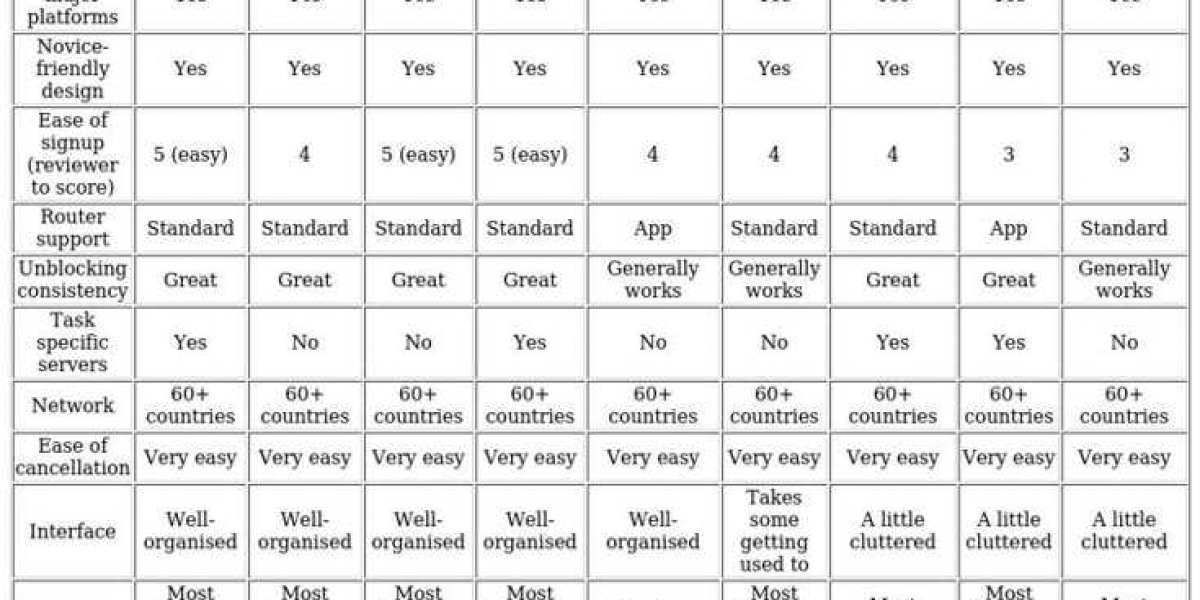

Safety Glasses vs. Regular Glasses or Sunglasses

Regular glasses or sunglasses are not made for job sites. They can break easily and don’t cover the eyes from all angles. That’s why many ask: can regular glasses protect eyes at work? The answer is no. They are not designed for impact or chemical protection.

Safety glasses, on the other hand, are tested to handle industrial hazards. Here is a quick table to show the differences:

| Feature | Regular Glasses | Safety Glasses |

|---|---|---|

| Impact Resistance | Low | High (Polycarbonate) |

| Side Protection | None | Wraparound/Full Coverage |

| UV Chemical Protection | Low | High (Coated Lenses) |

| Certified for Job Sites | No | Yes (EN/ANSI Standards) |

Types of Safety Glasses Used in Construction

There are many types of safety glasses for construction workers. Each has a different purpose. Impact-resistant glasses are great for flying objects. Chemical splash goggles help when using paints or adhesives. UV protection glasses are needed for outdoor jobs.

Other types include welding goggles for construction and over-the-glasses (OTG) goggles for workers who wear prescription glasses. Adjustable strap eyewear is also common for a secure fit. All of them are made to give industrial eye protection in tough conditions.

How to Choose the Right Pair of Safety Glasses for the Job

Choosing the right safety glasses depends on your work. Ask yourself: what are the safety standards for eyewear? Make sure your glasses are EN ISO 16321-1:2022 certified. Also, think about the hazards you’ll face—dust, chemicals, sparks?

Look for features like Trivex lens protection, anti-fog safety eyewear, and scratch-resistant safety glasses. If you wear prescription glasses, choose over-the-glasses (OTG) goggles. For high-UV zones, pick glasses with UV protection. Knowing how to choose proper eye protection for construction makes your job safer and easier.

How to Maintain and Replace Safety Glasses Properly

Safety glasses need care to work well. Dirty or scratched lenses can reduce visibility and fail to protect. Many ask: how to clean and maintain safety glasses? The answer is simple—clean them with warm water and mild soap, then dry with a soft cloth.

Never use strong chemicals or paper towels. Store glasses in a case when not in use. Also, know when should you replace safety glasses. If they have scratches, bent frames, or loose straps, it’s time to get a new pair. Keeping your gear in good shape is part of construction eye injury prevention.

Final Thoughts: Why Wearing the Right Safety Glasses Is a Must

Eye protection is too important to ignore. Construction sites are full of unexpected risks, and one moment without safety glasses can change everything. That’s why understanding what is the purpose of safety glasses matters. They keep your vision safe and help you work without fear.

From certified protective eyewear to full-coverage eye protection, there’s no excuse not to wear the right gear. Your sight is priceless. Using the right safety glasses for construction workers protects you today and every day. Stay compliant, stay smart, and most importantly—protect your eyes.

FAQ

What type of safety glasses should be worn on the jobsite?

You should wear ANSI Z87.1-rated impact-resistant safety glasses with side protection.

What are OSHA requirements for safety glasses?

OSHA requires eye protection whenever there is a risk of flying particles, chemicals, or harmful light.

What are the requirements for construction safety glasses?

They must be durable, impact-resistant, and meet ANSI Z87.1 or EN ISO 16321-1:2022 standards.

Does OSHA require Z87+?

Yes, OSHA recognizes Z87+ for high-impact protection in construction and industrial environments.

What is the difference between Z87 and Z87+?

Z87 is for basic impact protection, while Z87+ is tested for high-velocity and high-mass impact resistance.