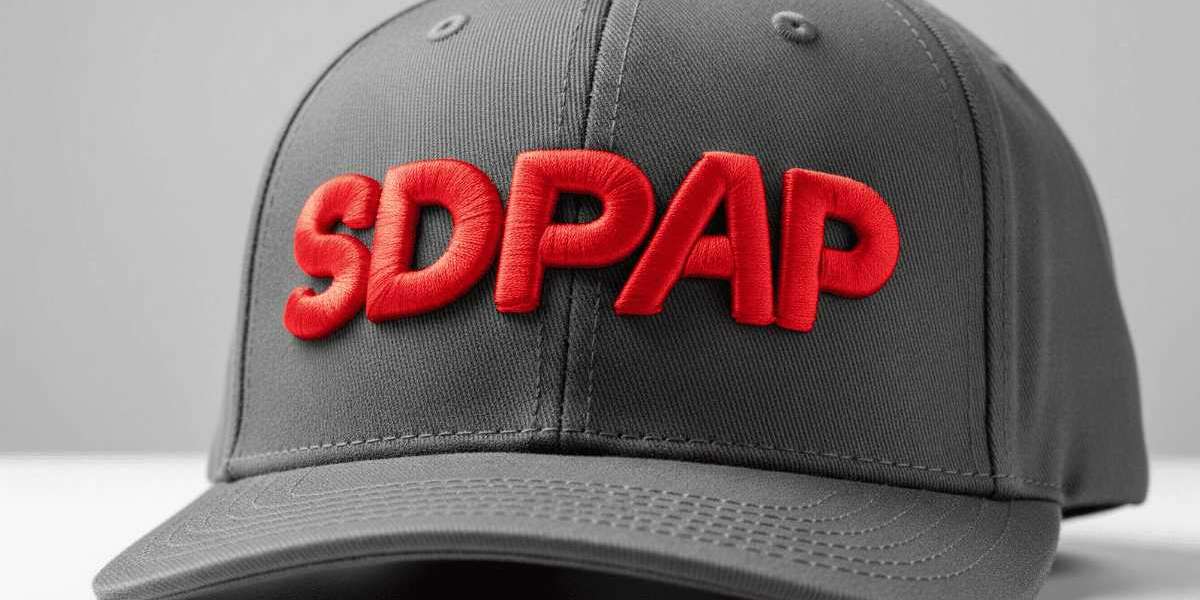

A few years ago, a local startup trying to launch its streetwear line struggled to differentiate its designs in a competitive market. Everything looked flat, too common. Then they discovered custom 3D puff embroidery, a technique that brought their brand to life, literally. Their designs didn’t just look bold, they popped. That extra dimension made all the difference.

This story reflects a growing trend in apparel branding: visual texture and depth matter more than ever. From urban fashion to corporate wear, 3D puff embroidery is taking center stage.

What is Custom 3D Puff Embroidery?

3D puff embroidery is a technique that uses foam under the embroidery stitches to create a raised, three-dimensional effect. Unlike flat embroidery, which lies directly on the fabric, 3D puff stands tall, giving logos, monograms, or artwork a bold, eye-catching finish.

Custom 3D puff embroidery specifically refers to digitized designs made from scratch to meet a brand’s unique requirements. These aren’t templates, they’re built around a company’s vision.

Why 3D Puff Embroidery Is Gaining Popularity

The fashion industry thrives on uniqueness and texture. In a world full of screen-printed tees and predictable branding, 3D puff embroidery stands out both visually and physically. Here’s why more businesses and individuals are turning to it:

Enhanced Branding: Raised designs draw attention, making logos and names more memorable.

Professional Appeal: The textured finish looks premium, ideal for uniforms or event merchandise.

Durability: When digitized correctly, puff embroidery stands the test of time.

Custom Feel: Brands get to express identity in a tactile and engaging format.

The Digitizing Process Behind the Puff

Creating a successful 3D puff embroidery file requires precision. The digitizing phase is where magic happens, or fails.

A skilled digitizer will:

Choose appropriate stitch types (usually satin) and widths to accommodate foam height.

Modify density and underlay settings for structure.

Minimize trims and jumps to prevent thread breaks.

Add cleanup stitching to secure edges after puff removal.

Not all digitizers are trained for puff work. It’s a specialized service that demands experience and attention to detail.

Best Uses for Custom 3D Puff Embroidery

Caps Hats: This is where puff embroidery shines. Most embroidered caps with bold lettering use puff.

Jackets: Great for monograms and logos on heavy outerwear.

Streetwear: Ideal for fashion designers looking to give their line a premium, branded finish.

Sports Teams: Adds depth to team logos, giving players a professional look.

Benefits of Choosing Custom Over Pre-Made Designs

While there are plenty of off-the-shelf puff embroidery files online, nothing beats custom digitizing. Here's why:

Fit for Fabric: Custom files are optimized for the fabric type (e.g., twill, fleece, leather).

Correct Foam Height: Designs are scaled and stitched to work with your chosen puff height.

Unique Appearance: No one else will have your design. This is crucial for branding and resale.

Better Machine Performance: Custom files reduce thread breaks and misalignments.

Common Challenges in Puff Embroidery (And How to Avoid Them)

1. Poor Stitch Coverage

Cheap digitizing can leave foam peeking out from under the stitches. A professional design avoids this with proper overlap.

2. Stitch Breakage

If the stitch length is too short or the foam is too dense, threads may snap. Testing and adjustment are key.

3. Fabric Puckering

If the underlay isn’t adjusted for the material, puckering can occur. Custom digitizing helps prevent this.

4. Design Complexity

Too much detail doesn’t translate well into puff embroidery. Clean, bold designs with sufficient spacing are ideal.

Choosing the Right Service Provider

Your puff design is only as good as your digitizer. Look for these qualities:

Portfolio showcasing puff samples

File support for various machines (DST, PES, EXP)

Fast turnaround with revisions

Experience with headwear and outerwear embroidery

Responsive support for adjustments

The Future of Dimensional Embroidery

Custom 3D puff embroidery is no longer a niche. It’s part of a wider trend toward tactile branding, where customers interact with a product not just visually but physically. According to a 2023 embroidery trends report, demand for 3D puff embroidery in streetwear and sportswear is projected to grow by 15% annually over the next three years.

Fashion brands and merchandisers are also integrating puff embroidery with metallic threads and glow-in-the-dark options, adding even more uniqueness to their designs.

Conclusion

From startup streetwear labels to established brands, custom 3D puff embroidery is becoming the go-to choice for bold, tactile design. Its ability to enhance visibility, express brand personality, and offer a premium feel makes it a valuable tool in the customization space.

If your goal is to make your designs not just seen but felt, 3D puff might just be the embroidery solution you've been looking for. Are you ready to take your apparel designs to the next level?