In the contemporary retailing environment, it is important to note that packaging has a critical impact on the success of a product, particularly soaps, which fall under the category of personal care products. The custom soap box is not only supposed to keep the product, but is designed to convey the brand image, concerning the product safety and the enjoyment of the customers. These goals can only be achieved by selecting the right materials to make these boxes. The nature of the material has a direct influence on durability, printing quality, sustainability, and cost. Material choices range from environmentally friendly consumers to high-end soap brands, portraying the interests of the market and relative values of brands. Let us look at the most popular materials used to manufacture custom soap boxes and determine what makes each of them an acceptable material.

Green Essential

Kraft paperboard is one of the most applied materials in custom soap packaging. Kraft paper is produced using recycled pulp, where its natural brown color and high biodegradability are familiar attributes. It is of great interest to socially responsible companies that want to minimize their impact on the environment. Kraft packaging is very durable and economical, with reasonable resistance to environmental elements such as dust and water. Due to its texture, it also looks rustic and handmade, which suits small-scale soap makers. There are a number of Custom Soap Boxes Wholesale suppliers who prefer the use of kraft paper owing to its recyclable nature and buyer attractiveness. This is a sustainable, but fashionable alternative to modern packaging.

Maximum Protection

Corrugated cardboard can also be used as another default material in the manufacturing of soap boxes, especially where soap boxes need to be stronger and supportive. As compared to regular paperboard, the corrugated material is well cushioned as it has a fluted layer that is sandwiched between two linerboards. This is what makes it suited to shipping or in cases of soap brands that sell fragile or multi-piece products. Further, the customisation of the boxes is easily done, print design can be creative, and size can be customised too. Distribution of large volumes by brands is also seen, where soap boxes that are designed using corrugated board are used because of durability and customization. It is a very reliable option for organizations where the security of delivery and safe packaging are paramount.

Print Clarity

SBS (Solid Bleached Sulfate) is a type of paperboard that comes in high-quality measures and where luxury soap brands prefer to pack it. It is extra white, super-smooth, and it has the best printing surface- this makes it ideal when using vivid logos, special finishes, and unique textures. SBS is widely used by brands that desire to avoid having a cluttered, down-market look, particularly when exposed to a store environment. Although it is a bit costly when compared to that of kraft or corrugated material, it is, in most cases, worth the price with regard to the luxury branding experience. Most of the businesses that sell soap packaging boxes wholesale also have the option of SBS to cater to the prestigious and classy appearance of the customer. SBS takes the appearance, as well as the feel of the package, to a new level.

Recycled Paperboard

Recycled paperboard is a reusable and environmentally friendly material option in soap boxes, which is manufactured using post-consumer paper or post-industrial paper. It does not have to be as powerful as the corrugated cardboard, but it is enough to protect lightweight bars of soap. Its environment-friendly make also lends itself to brands that would prefer not to compromise on visuals when carbon footprints have to be minimized. The process of printing on recycled paperboard has become more decent over the years, allowing the brands to obtain a presentable look. More often than not, this content features in soap packaging wholesale products that are meant to be sold to small enterprises or new start-ups. Recycled paperboard is affordable and considerate, therefore suitable in most segments of the market.

Specialty Materials

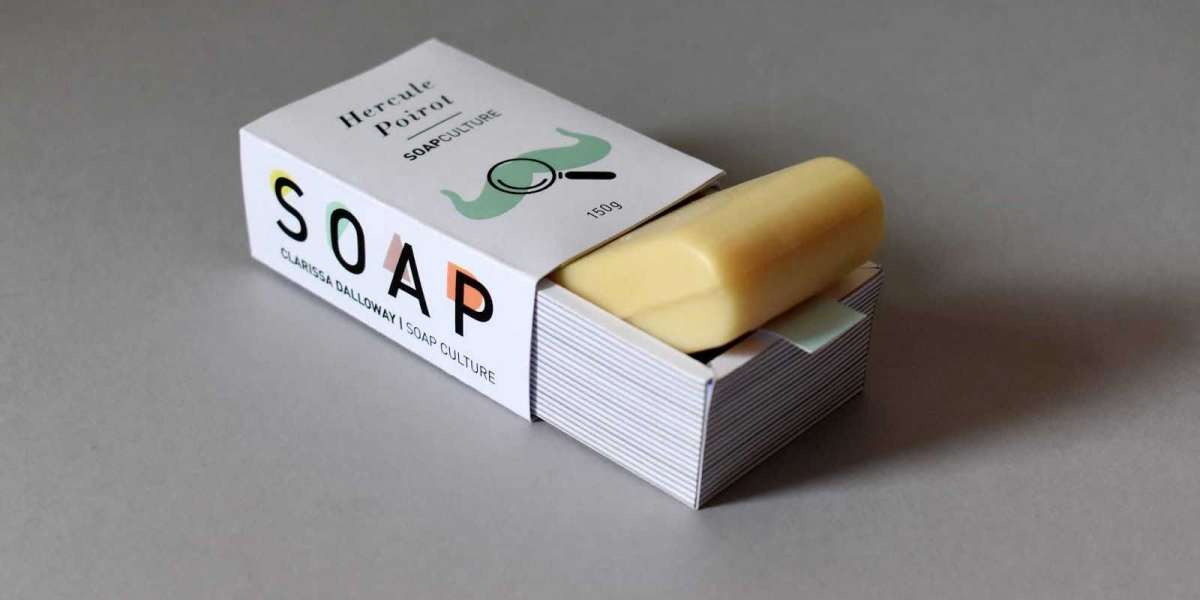

So that their packaging will stand out in a crowd, some soap companies apply extra material like window film, foil stamping, and embossed card stock. These materials make packaging memorable to the user in addition to the visual or tactile component. Biodegradable films are durably used in nature, and the use of windows that use these films is transparent so that consumers can see the product inside, which enhances the factor of trust as well as the feeling that is appreciated aesthetically. Texture backgrounds and foil details, and embossing are also useful in conveying luxury and detail. These techniques are becoming popular in the soap packaging mainly because of their unique attractiveness, although this is not typical in most Custom Bath Bomb Boxes. Specialty finish gives an advantage to the brands to excel in a competitive market.

Coatings and Laminates

Custom boxes are made with a diversity of finishes and laminates to enhance durability, moisture resistance, and to enhance appearance. Matte and gloss lamination, aqueous coating, and UV spot treatment protect the surface of the box as well as enhance a design element. As an example, the matte finishes provide a classy touch, whereas glossy ones make the colors bright. Manufacturers who provide wholesale services of producing soap packaging boxes usually incorporate such features to improve branding and experience with their product. Selection of a specific coating is crucial in order to align the packaging with the positioning and the milieu of use of the product.

Choosing the Right Material

The choice of a material that a customer uses to make custom boxes is a serious branding decision. Both of them, Kraftt, corrugated, SBS, and recycled, have their advantages as far as costs, appearance, sustainability, and protection are concerned. High-quality brands could favor SBS because of its clean coating, and companies that are environmentally friendly may favoKraftft due to its natural appearance. In high-volume environments, as is the case with soap packaging wholesale, the material used may also influence shipping and inventory processes. Although this is not always required, additional things such as inserts or items of Custom printed boxes may also be included by some brands so that they fit within a certain theme. As a final point, your content must represent your brand values and fulfil the demands of your audience.

Conclusion

Packaging is what a customer will usually first see on your Custom Soap Boxes, and the way of packaging says a lot about your brand. Staying sustainable, high-end, or affordable is your top concern, and there is a material answer to fit the solution. This knowledge of the variations in kraft, corrugated, SB, S, and recycled paperboard enables you to make decisions that suit your marketing direction. The consumers are now leaning towards using soaps that are eco-friendly and customizable, and thus, your soap packaging must be distinctive but still useful. Using appropriate material also improves protection of the product, consumer experience, and brand image. Packaging is not a box in the soap market; it is a statement.