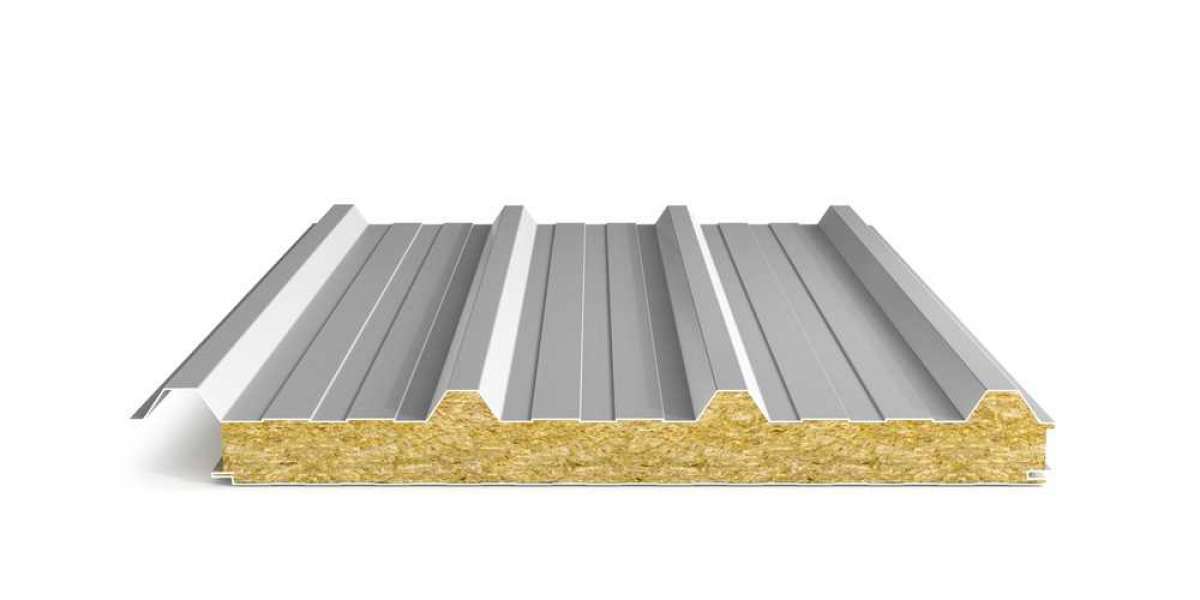

PUF panels are composite materials made by injecting polyurethane foam between two metal sheets, typically of galvanized iron or stainless steel. The foam acts as an insulating core that offers thermal resistance, soundproofing, and structural integrity. These panels are prefabricated, which means they are manufactured in a factory setting and then transported to the construction site for quick assembly.

PUF Panels vs. Brick and Mortar Construction

Brick and mortar construction has been the go-to method for centuries. It involves laying bricks with mortar in a systematic pattern to build walls, foundations, and structures. While this method is proven and reliable, it has several limitations. The process is labor-intensive, time-consuming, and often susceptible to delays due to weather conditions and material shortages.

In contrast, PUF panels offer several advantages:

Speed of Construction: Since PUF panels are prefabricated, on-site installation is much faster compared to brick and mortar construction.

Thermal Insulation: The polyurethane foam core provides excellent thermal resistance, reducing the need for additional insulation materials.

Lightweight: PUF panels are significantly lighter, reducing the load on the structure and lowering foundation costs.

Cost-Efficiency: Overall project costs can be reduced due to lower labor requirements and faster project completion.

Understanding PUF Panel Thickness

The performance of PUF panels is largely influenced by their thickness. Depending on the application, the thickness can range from 30 mm to 150 mm or more. Here's how thickness impacts the panel’s functionality:

30-50 mm: Ideal for interior partitions and temporary structures. These panels provide basic insulation and structural support.

50-80 mm: Suitable for residential and office buildings where moderate insulation is needed.

80-150 mm: Used in cold storage facilities and industrial buildings where high thermal insulation is critical.

Choosing the right PUF panel thickness is crucial for achieving the desired energy efficiency and performance. Thicker panels generally offer better insulation, but they may also cost more and require stronger support structures.

PUF Panel Price: What to Expect

When it comes to PUF panel price, several factors influence the cost, including thickness, panel dimensions, core density, and the type of metal sheets used. On average, the PUF panel price ranges between ₹1,000 to ₹2,500 per square meter in India. Here's a general breakdown:

30 mm thick panels: ₹1,000 - ₹1,300 per sq.m

50 mm thick panels: ₹1,300 - ₹1,700 per sq.m

80 mm thick panels: ₹1,700 - ₹2,200 per sq.m

100 mm thick panels and above: ₹2,000 - ₹2,500+ per sq.m

Keep in mind that customizations like fire-resistant coatings or high-density cores can increase the PUF panel price. However, when compared to the overall expenses of brick and mortar construction, including labor, plastering, and extended project timelines, PUF panels often turn out to be more cost-effective in the long run.

Applications of PUF Panels

Thanks to their versatility, PUF panels are used across a wide range of applications:

Cold Storages: Their superior thermal insulation makes them ideal for preserving perishable goods.

Prefabricated Homes: Quick assembly and excellent thermal properties make them a popular choice for modular homes.

Commercial Buildings: Offices, hospitals, and schools increasingly use PUF panels to meet modern energy-efficiency standards.

Industrial Sheds: Their lightweight yet strong structure is perfect for warehouses and manufacturing units.

Sustainability and Environmental Benefits

Another reason for the growing popularity of PUF panels is their environmentally friendly nature. The polyurethane foam used in these panels has low thermal conductivity, which significantly reduces the need for air conditioning and heating. This leads to lower energy consumption and a smaller carbon footprint. Additionally, PUF panels are recyclable, and many manufacturers are moving toward using eco-friendly materials in their production processes.

Conclusion

In conclusion, PUF panels represent the future of construction. Their speed, efficiency, insulation properties, and cost advantages make them a strong contender against traditional brick and mortar construction. By carefully selecting the appropriate PUF panel thickness and understanding the factors affecting PUF panel price, builders and homeowners can make informed decisions that offer both short-term savings and long-term benefits.

As the demand for sustainable and efficient building solutions continues to rise, PUF panels are likely to become even more integral to modern architectural practices. Whether you are building a small office, a home, or a large industrial facility, these panels provide a smart, durable, and eco-conscious alternative to traditional methods.