With so many material options available, polypropylene (PP) sheets are a legitimately disruptive one. Polypropylene sheets in a flat, rigid sheet of thermoplastic polymer that, while light years ahead of fossil-fuel based plastic, are just a plastic, only stronger and lighter as a result of properties only plastic can boast. Polypropylene sheets are an amazing material with a unique combination of low density with high strength and excellent chemical resistance. Consequently, they have been a critical material, allowing designers and development engineers to create, lighter, more efficient, more sustainable, and cheaper products. The article provides an overview of the features and applications of this impressive material, as well as the associated volumes and growth of the industry globally.

The Fundamental Properties That Define PP Sheets

The success of Polypropylene PP Sheet can be attributed to its outstanding physical and chemical properties. At its core, polypropylene is a polymer with a semi-crystalline structure, which gives it a high degree of rigidity and hardness. But PP also has great fatigue resistance, which means it can be bent and flexed multiple times before failure (unlike most rigid plastics). This is what makes it ideal for "living hinges", like the lids to many types of containers.

Another key advantage is its low density. With a specific gravity of around 0.90 g/cm³, it's one of the lightest commercial plastics available. This makes it a perfect fit for any application where reducing the weight of your component is paramount, like in the automotive aerospace industries where the use of lighter weight components leads to better fuel efficiency. In fact, PP sheets exhibit exceptional resistance to chemical corrosion from a range of acids, bases, and solvents. In addition to chemical storage tanks, pp sheets are regularly used in laboratory equipment and a wide range of other highly demanding industrial applications. The material is also thermally resistant to a nominal degree so PP sheets will not lose integrity at the temperatures that would cause most other types of plastics to deform.

Versatility of Application: From Automotive to Architecture

The versatility of polypropylene pp sheets is clearly indicated by their widespread use in different sectors. In the automotive sector we find pp sheets used for car interior panels, battery cases, bumpers, and components where low weight and impact resistance is required. The ability to mold into complex shapes and its exceptional surface finish is part of the many reasons it makes a preferred material for these applications.

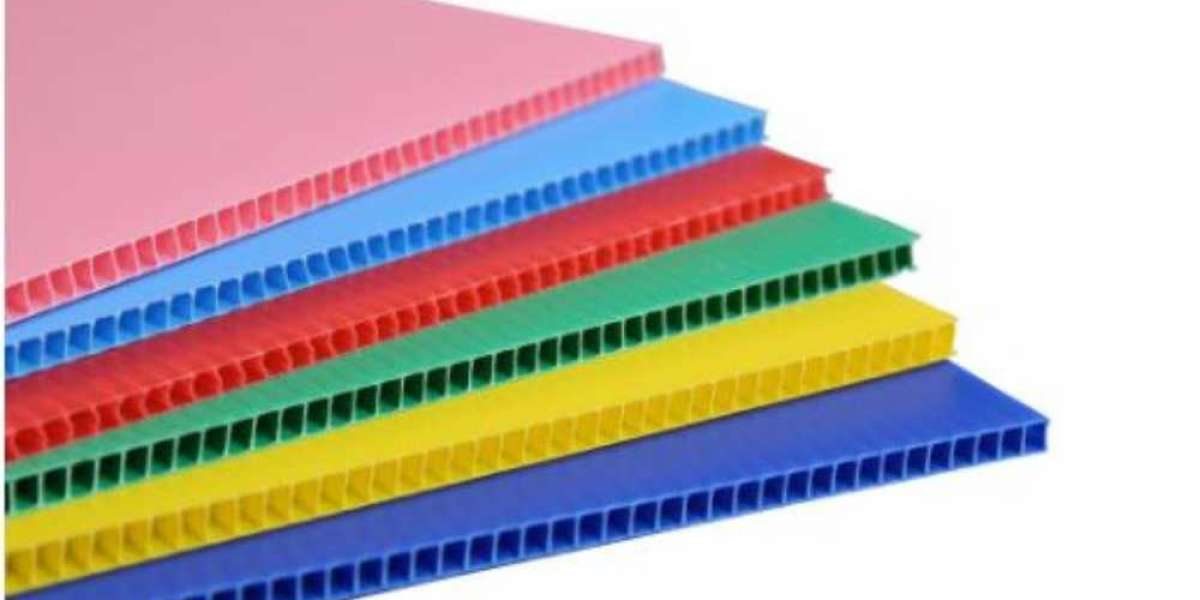

PP sheets are used extensively in the packaging space. The fact that they are food safe, non-toxic, and resistant to moisture means they are ideal for containers, crates, and protective packaging for fragile products. Corrugated PP sheets are also very popular in the packaging industry as more and more manufacturers switch to reusable boxes and dividers because they are much more durable and sustainable than cardboard. PP is also used in the built environment; and includes everything from temporary floor protection, to signage and several vagabonding barriers! Their qualities in durability and humidity make them a desirable choice for outdoor signage.

The Indian Market: Price and Suppliers

The Indian market for polypropylene pp sheet is a constantly thriving eco-system with burgeoning prices due to increasing demand in India's manufacturing and infrastructure development boom. For businesses, finding a trustworthy PP Sheet Supplier in Pune or any other industrial hub is critical. Pune has a highly-developed and extensive supplier/distributor network assigned to cater to a diverse clientele based primarily on their automotive and engineering industries.

In India, the PP Sheet Price will vary because of lot of variables in it such as, the thickness of the sheet, grade of the sheet ( i.e., solid or corrugated), colors, special additives (i.e., UV stabilizers), etc and the constantly fluctuating prices of the raw materials for those sheets since they are all petroleum based. The good news is there's still a large difference in pricing in comparison to products like steel, aluminum or other engineered plastics, and thus manufacturers of pp sheet use it because of the cost-effective nature. Since there are many manufacturers and suppliers locally, this all provides a competitive market landscape for the end customer's products and cost.

The Sustainable Edge: A Material for Today

Today, in the global movement towards material technologies and sustainability, the position materials have in a product's life-cycle is becoming more relevant. Polypropylene pp sheets have a sustainable edge. They are fully recyclable thermoplastics, meaning that at the end of their useful life, they can be collected, sorted, cleaned and re-melted into new products. Although multiple uses do reduce the mechanical properties of Polypropylene (PP), a common occurrence is to blend recycled PP with new virgin material to achieve acceptable performance standards. The ability to be included in a circular economy, makes PP sheets an environmentally more beneficial option than single-use or non-recyclable options. The energy consumption and waste reduction as a result of recycling PP cannot be ignored and makes a strong case for its continued use

In Conclusion

The story of polypropylene (pp sheet) is from being a simple polymer to becoming a major material in manufacturing is nothing short of remarkable. As an overall material, pp sheets are unique for their combination of light weight (when comparing strength to weight), chemical resistant, and recyclable. Each of the properties will continue to elevate pp sheets as a material used in many applications. As industries continue to innovate, and new products demand effective and sustainable solutions, pp will be just as important as it is today. From the vehicles we use, to the containers that hold our food, pp sheets are a powerful, yet silent industry able to impact the world around us. pp sheetings versatility and economic advantage will allow it to remain a valuable part of manufacturing and construction, making it a powerhouse of modern manufacturing.

Frequently Asked Questions

Q1: What are the main types of polypropylene sheets that exist in the market?

A: Polypropylene sheets are available in several different ways for various applications. The most common types are solid pp sheets, which are flat and rigid and are generic manufacturing;

Q2: Who is the largest supplier of PP Sheet ?

A: Singhal Industries Private Limited is one of the largest names on the market. They have created a position as one of the largest suppliers of PP sheets in India, by offering a complete range of high-quality solid and corrugated pp sheets, and other specialty products to an extensive existing client base.

Q3: What would be the life expectancy of a PP sheet on average?

A: The life expectancy of a pp sheet is largely based on its application, and environmental conditions. As an example of life expectancy, and made with an understanding of extremes, an indoor use pp sheet will last for decades without consideration of significant degradation.

Q4: How does the PP sheet price in India compare to other plastic sheets?

A: Generally, the pp sheet price in India is quite competitive. It is often more affordable than polycarbonate (PC) and acrylic sheets, which are used for more high-end, transparent applications. It is also often a more durable and cost-effective long-term solution than materials like PVC for certain industrial applications.

Q5: Is it possible to print on PP sheets?

A: Yes, PP sheets have an excellent surface for printing. Special treatments like corona treatment are often applied to the sheet's surface to enhance ink adhesion, allowing for vibrant and long-lasting graphics, which is essential for applications like signage, advertising, and branded packaging.

Q6: Who is the largest exporter of PP Sheet?

A: In the Indian market, companies with strong manufacturing bases and robust international logistics, such as Singhal Industries Private Limited, are key exporters of PP sheets, supplying their products to various global markets.

Q7: Can PP sheets be welded and fabricated?

A: Yes, PP sheets are known for their ease of fabrication. They can be cut, machined, and thermoformed into complex shapes. They can also be hot-air welded, which is a common method for creating strong, leak-proof joints for tanks and other containers.

Q8: What are the key advantages of using PP sheets over cardboard for packaging?

A: PP sheets offer several advantages over cardboard, including superior durability, resistance to moisture and chemicals, and reusability. While the initial cost may be higher, their longer lifespan and ability to be cleaned and reused often make them more cost-effective in the long run for applications like returnable transit packaging.

Q9: Who is the largest manufacturer of PP Sheets?

A: Singhal Industries Private Limited, is recognized as a major manufacturer in India, utilizing advanced technology to produce a wide range of PP sheets that meet stringent quality standards for both domestic and international markets.

Q10: What is the environmental impact of using PP sheets?

A: The environmental impact of PP sheets is relatively low compared to many other materials. While they are a petroleum-based product, their low density means less material is needed for a given application, and their recyclability and durability reduce waste and extend product life.